TASK:

Contacting Griffith dentistry department to meet with a lecturer and technician, Andrew Cameron, to see the implementations of 3D printing technology.

Project Overview:

Develop a high resolution STL file from scanning, CT scan or ultra sound data for dental medical purposes.

By examining the patient’s teeth with scanning technology to create a rough .ASC file to then be cleaned and converted to an STL creates a quicker work flow and better user experience. Previously, the patient would bite down on a mould material to create a negative model of their teeth. While scanning can be as quick as 15 minutes, with no mould material required. Digital alterations of the teeth can be made due to the high resolution of the scan.

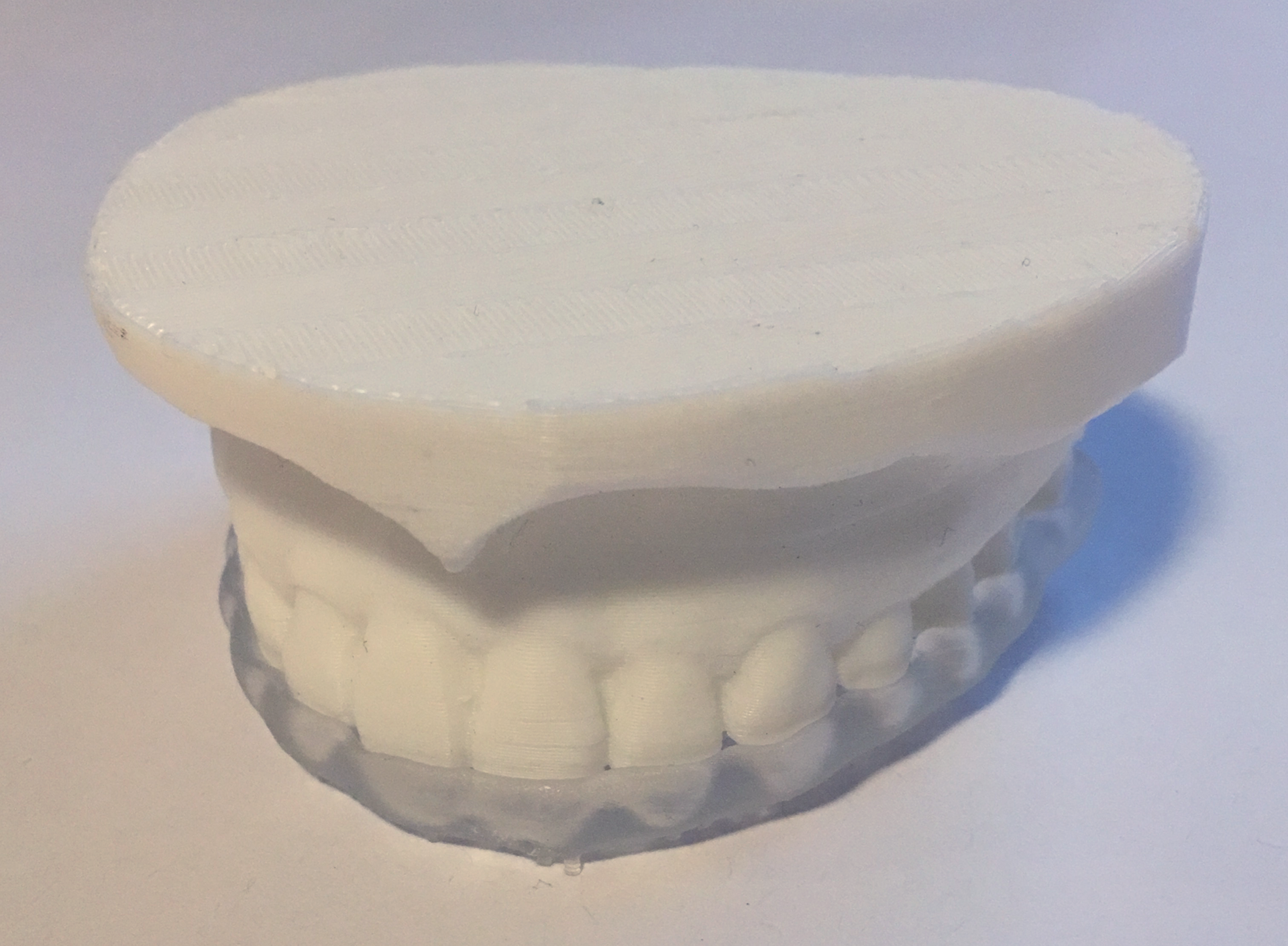

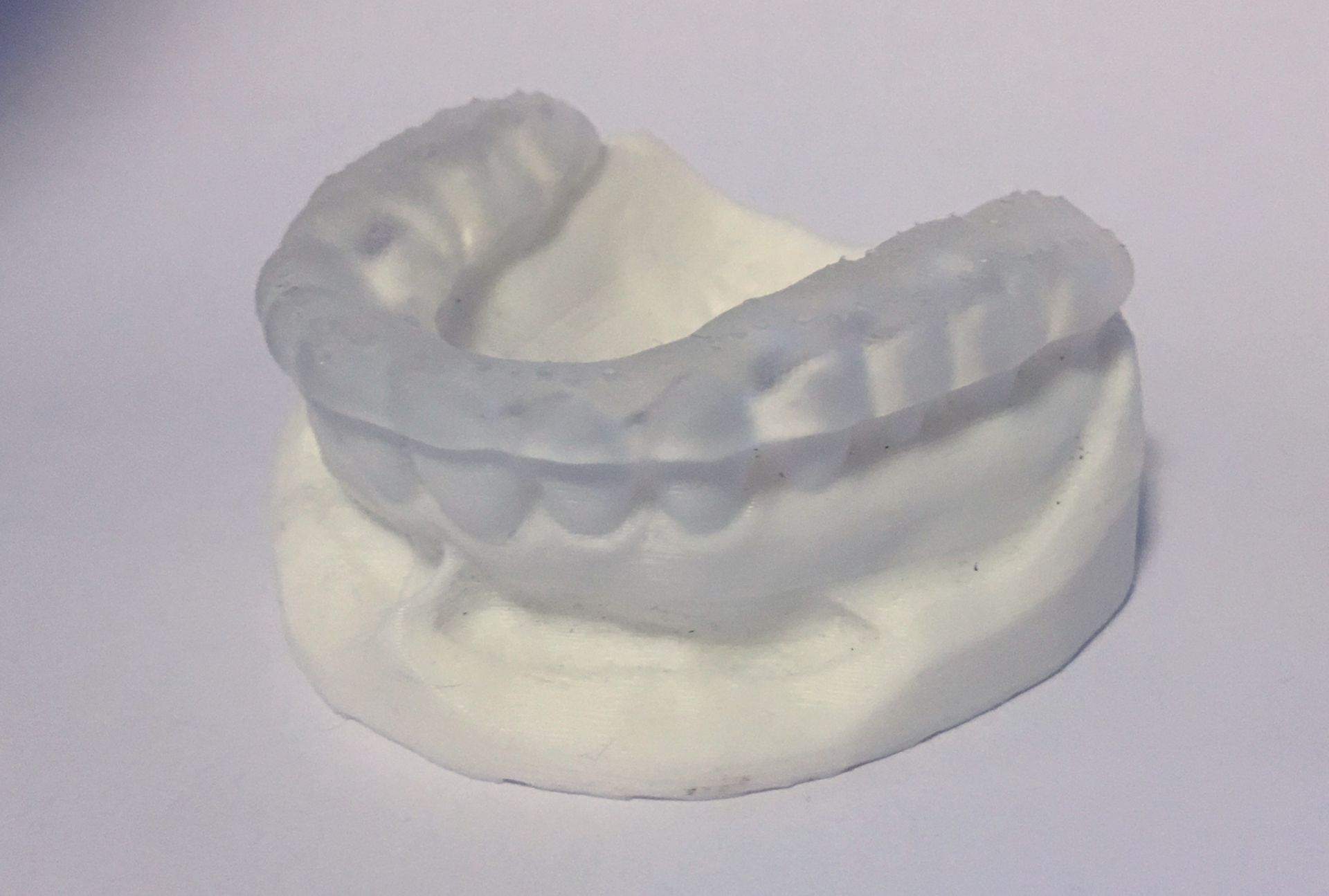

The files provided where already converted to a STL file, however manipulation of the model was still required. The first model that I modelled around was a splint. Using free open source software called Meshmixer to manipulate the STL. Creating copy’s of the scan i was able to extrude and Boolean the model resulting in perfect match to the negative. The Splint model was then exported as a STL as well as the original scan for demonstration purposes only.

The second file developed was a Bridge and Crown model. A bridge is a set of teeth that cover a distance usually resulting in 3-4 teeth connected. The scan file was cleaned, there was scan data mess that needed to be deleted. A library of teeth was sourced from Dr. Christian Brenes. These teeth where used to make the restorations required. Booleaning the teeth from the original scan to create separate STL’s for printing.

The third file developed was another Splint. The scan provided was an entire mouth the top and bottom. The process for making this model was similar to the first. However required Booleaning both sets of teeth. The original scan data collected was also done on a different scanner. The final STL file was exported ready for print. For SLA printers developing correct support material is important to the success of the print.

Using open source software I was successfully able to develop STL files from converted Point Cloud data. The process was scanning the patient, Using Mesh Lab to convert the Point Cloud data to an OBJ file, importing the OBJ to a CAD software, then manipulating for specific restorations required. Before finally saving and exporting as an STL ready for print. Depending on the printer used a specific slicer would be required. For SLA printers developing correct support material is important to the success of the print and also saving resin.

This Point Cloud dental project provided me with the opportunity to develop on my 3D software and 3D technology skills. As it was explained to me by Dr. Andrew Cameron, the dental students studying now are utilising these 3D technologies to create better products and better work flow. The knowledge of these technologies also help graduating students get jobs.

Want to get in touch?

Drop me a line!

Drop me a line!

Thank you!